Seals Eastern, Inc.

Rubber Analysis Capabilities

Tel: 732-747-9200

Seals Eastern's Material Development Center is equipped with state-of-the-art instruments for quantifying elastomeric material properties for research, development, QA, and forensic support. Our equipment includes:

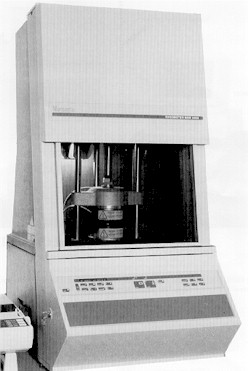

Used to characterize the cure profile for all Seals Eastern compounds. A sample of uncured rubber is

placed between the rheometer plates; the plates are then closed, forming a

sealed cavity. The plates are maintained at 330° F while one plate

oscillates. The stationary plate is equipped with a torque

transducer, which records the induced torque as time and curing progress.

Used to characterize the cure profile for all Seals Eastern compounds. A sample of uncured rubber is

placed between the rheometer plates; the plates are then closed, forming a

sealed cavity. The plates are maintained at 330° F while one plate

oscillates. The stationary plate is equipped with a torque

transducer, which records the induced torque as time and curing progress.

Seals Eastern utilizes Fourier transformed infrared spectral data for Quality Control and chemical analysis of

rubber compounds and ingredients.

Seals Eastern employs a computer integrated FTIR instrument

to perform such analysis. We use the Nicolet® Model 460 bench combined with a Spectra-Tech Thunderdome ATR (Attenuated Total

Reflectance) accessory as an extremely powerful tool for analysis of

elastomer composition and chemical degradation. FTIR enables us to examine

the presence or changes of functional organic groups present within the

rubber composition.

rubber compounds and ingredients.

Seals Eastern employs a computer integrated FTIR instrument

to perform such analysis. We use the Nicolet® Model 460 bench combined with a Spectra-Tech Thunderdome ATR (Attenuated Total

Reflectance) accessory as an extremely powerful tool for analysis of

elastomer composition and chemical degradation. FTIR enables us to examine

the presence or changes of functional organic groups present within the

rubber composition.

Seals Eastern utilizes an ARES to characterize and analyze the

viscoelastic properties of its materials. The ARES Strain-Controlled Rheometer,

by Rheometric Scientific, is an advanced instrument capable of mechanical polymer characterization.

The instrument is capable of a wide range of testing from steady shear to

multi-wave temperature sweeps. The instrument is capable of testing in the temperature range of -150° C to

600° C. Dynamic tests can be performed at frequencies between 10-5 rad/s

and 500 rad/s.

Flow and stress relaxation phenomena are easily observed using the ARES

instrument. To learn more about Dynamic Mechanical Thermal Analysis

read Luckenbachs paper (note:

you will need Acrobat Reader to down load this paper).

The instrument is capable of a wide range of testing from steady shear to

multi-wave temperature sweeps. The instrument is capable of testing in the temperature range of -150° C to

600° C. Dynamic tests can be performed at frequencies between 10-5 rad/s

and 500 rad/s.

Flow and stress relaxation phenomena are easily observed using the ARES

instrument. To learn more about Dynamic Mechanical Thermal Analysis

read Luckenbachs paper (note:

you will need Acrobat Reader to down load this paper).

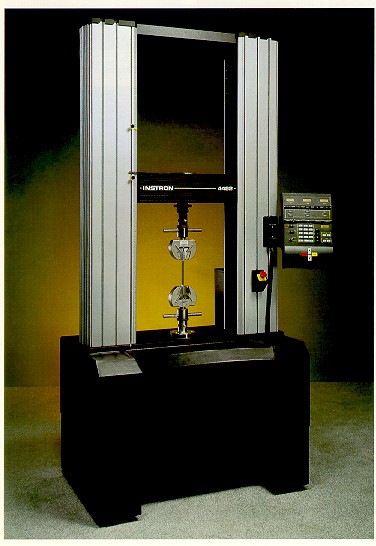

For standard (and some non-standard) measurements of rubber properties,

Seals Eastern, Inc. has two Instron tensile testing

machines. The Model 4400R and Model 1122 are equipped to perform tensile and

peel tests of virtually any rubber compound. Both machines are computer

integrated for precise data collection and generation of stress - strain

curves as well as integration of the area under the stress- strain curves. Standard tests include: ASTM

D429 Method B Peel Test, ASTM D1414 O-Ring Tests, ASTM D412 Tensile Tests.

For standard (and some non-standard) measurements of rubber properties,

Seals Eastern, Inc. has two Instron tensile testing

machines. The Model 4400R and Model 1122 are equipped to perform tensile and

peel tests of virtually any rubber compound. Both machines are computer

integrated for precise data collection and generation of stress - strain

curves as well as integration of the area under the stress- strain curves. Standard tests include: ASTM

D429 Method B Peel Test, ASTM D1414 O-Ring Tests, ASTM D412 Tensile Tests.

Premium Quality Seals...

Premium Quality Seals...

For a Cleaner, Safer, More Reliable World.TM