Seals Eastern, Inc.

Rubber Seals, Gaskets, and O-rings

Engineered and Manufactured to Your Solve Sealing Problems

Tel: 732-747-9200

Tel: 732-747-9200

A high pressure, high temperature

combination of natural gas, carbon dioxide and hydrogen sulfide is a

harsh environment for any rubber seal. However, Seals Easterns

contribution of advanced technical papers and patents have tackled the

problems. Consequently, we are a major supplier of high temperature,

high pressure seals, o-rings,

and packer elements that can help you solve some of your toughest

oilfield problems.

combination of natural gas, carbon dioxide and hydrogen sulfide is a

harsh environment for any rubber seal. However, Seals Easterns

contribution of advanced technical papers and patents have tackled the

problems. Consequently, we are a major supplier of high temperature,

high pressure seals, o-rings,

and packer elements that can help you solve some of your toughest

oilfield problems.

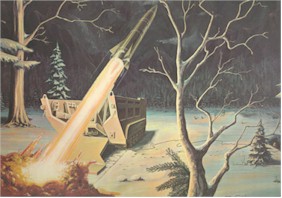

Seals Eastern was the sole-source for all fuel and oxidizer seals in

the "Lance" missile system. Fluoro-silicone and

phenyl-silicone rubber were bonded to large aluminum retainers.

Extensive studies on cross-linking, bonding technology, and surface

chemistry resulted in the production of a successful missile system.

Today, that experience has enabled us to consistenly manufacture high

integrity rubber to metal bonded components for your demanding

requirements.

Seals Eastern was the sole-source for all fuel and oxidizer seals in

the "Lance" missile system. Fluoro-silicone and

phenyl-silicone rubber were bonded to large aluminum retainers.

Extensive studies on cross-linking, bonding technology, and surface

chemistry resulted in the production of a successful missile system.

Today, that experience has enabled us to consistenly manufacture high

integrity rubber to metal bonded components for your demanding

requirements.

A low warranty cost engine requires seals able to

resist

stress-relaxation. Seals Eastern supplies millions of

low compression-set seals that ensure leak-free service in

heavy-duty diesel engine applications. Our seals have outstanding

long-term performance in the presence of traditional coolants and the

Organic Acid Technology ("OAT") coolants. Our seals

also withstand modern engine oils that have been formulated to

withstand higher operating temperatures. We can help you improve the

reliability of your engines with our leak-free seals.

stress-relaxation. Seals Eastern supplies millions of

low compression-set seals that ensure leak-free service in

heavy-duty diesel engine applications. Our seals have outstanding

long-term performance in the presence of traditional coolants and the

Organic Acid Technology ("OAT") coolants. Our seals

also withstand modern engine oils that have been formulated to

withstand higher operating temperatures. We can help you improve the

reliability of your engines with our leak-free seals.

A rapid decrease in pressure for seals in

high-pressure applications can be a recipe for

failure. In fact,

rubber has a predictable swelling response in high-pressure gases such

as methane, carbon dioxide, and hydrogen sulfide. The destructive

consequences of this swelling is not so much during the absorption but

when the system pressure is suddenly relieved. In the phenomena of

explosive decompression ("ED"), the gas absorbed by the

polymer expands rapidly, as described by Boyles law, upon the release

of system pressure. The consequences to a seal are catastrophic. Such

failure can occur in gas compressors, down-hole applications, and

other situations where high pressure is commonly encountered. Since

the 1980s, Seals Eastern has supplied

explosive decompression resistant seals

to major manufacturers of turbines, compressors, gas re-injection

equipment, pumps, and other fabricators who must mitigate the effects

of high-pressure gases in their equipment.

rubber has a predictable swelling response in high-pressure gases such

as methane, carbon dioxide, and hydrogen sulfide. The destructive

consequences of this swelling is not so much during the absorption but

when the system pressure is suddenly relieved. In the phenomena of

explosive decompression ("ED"), the gas absorbed by the

polymer expands rapidly, as described by Boyles law, upon the release

of system pressure. The consequences to a seal are catastrophic. Such

failure can occur in gas compressors, down-hole applications, and

other situations where high pressure is commonly encountered. Since

the 1980s, Seals Eastern has supplied

explosive decompression resistant seals

to major manufacturers of turbines, compressors, gas re-injection

equipment, pumps, and other fabricators who must mitigate the effects

of high-pressure gases in their equipment.

Poorly engineered rubber compounds can cause big problems. Some

suppliers simply resell what they can source without any real control

or ownership of the supply chain. By utilizing our complete vertical

integration of manufacturing resources, Seals Eastern quickly solved a

serious fuel system leaking problem for an internationally recognized

shipping fleet. This customer understood and benefitted from the value

of our integrated manufacturing and comprehensive

services. We can do the same for you...

Contact Us

Poorly engineered rubber compounds can cause big problems. Some

suppliers simply resell what they can source without any real control

or ownership of the supply chain. By utilizing our complete vertical

integration of manufacturing resources, Seals Eastern quickly solved a

serious fuel system leaking problem for an internationally recognized

shipping fleet. This customer understood and benefitted from the value

of our integrated manufacturing and comprehensive

services. We can do the same for you...

Contact Us

Premium Quality Seals...

For a Cleaner, Safer, More Reliable World.TM