Seals Eastern, Inc.

Rapid Gas Decompression Resistant

& Extrusion Resistant

Seals, Gaskets, and O-rings for high-pressure gas mixtures

Tel: 732-747-9200

Tel: 732-747-9200

When you have invested in a high pressure gas re-injection project,

the last thing you want is faulty seals shutting down your

multi-million dollar investment. An unexpected lubricant or the

introduction of corrosion inhibitors in the gas stream is all it

takes to destroy a poorly formulated sealing compound. Likewise, an

unexpected change in the gas composition, such as excessive carbon

dioxide or hydrogen sulfide (sour gas) can cause dangerous problems.

Seals Eastern formulates its high pressure seals for

assurance against aggressive chemicals and gases while maintaining the

ultimate mechanical properties in the seals. Our high pressure sealing

compounds keep you and your customers out of trouble.

takes to destroy a poorly formulated sealing compound. Likewise, an

unexpected change in the gas composition, such as excessive carbon

dioxide or hydrogen sulfide (sour gas) can cause dangerous problems.

Seals Eastern formulates its high pressure seals for

assurance against aggressive chemicals and gases while maintaining the

ultimate mechanical properties in the seals. Our high pressure sealing

compounds keep you and your customers out of trouble.

Rapid gas decompression ("RGD") in

high-pressure applications can be a recipe for

seal failure. In fact, elastomers have a predictable swelling response

in high-pressure gases such as CNG (compressed natural gas), methane,

carbon dioxide, and hydrogen sulfide (sour gas). The destructive

consequences of this swelling is not so much during the absorption of

the gas but when the system pressure is suddenly relieved. In the

phenomena of explosive decompression

("ED"), the gas absorbed by the polymer expands rapidly

within the polymer upon the release of

seal failure. In fact, elastomers have a predictable swelling response

in high-pressure gases such as CNG (compressed natural gas), methane,

carbon dioxide, and hydrogen sulfide (sour gas). The destructive

consequences of this swelling is not so much during the absorption of

the gas but when the system pressure is suddenly relieved. In the

phenomena of explosive decompression

("ED"), the gas absorbed by the polymer expands rapidly

within the polymer upon the release of

ambient pressure. The consequences to a seal can be catastrophic

failure. Such failure can occur in gas compressors, down-hole

applications, and other situations where high pressure is commonly

encountered. Since the 1980s, Seals Eastern has supplied

rapid gas decompression resistant seals to major

manufacturers of turbine driven compressors, gas re-injection

equipment, pumps, and other fabricators who must mitigate the effects

of high-pressure gases in their equipment.

ambient pressure. The consequences to a seal can be catastrophic

failure. Such failure can occur in gas compressors, down-hole

applications, and other situations where high pressure is commonly

encountered. Since the 1980s, Seals Eastern has supplied

rapid gas decompression resistant seals to major

manufacturers of turbine driven compressors, gas re-injection

equipment, pumps, and other fabricators who must mitigate the effects

of high-pressure gases in their equipment.

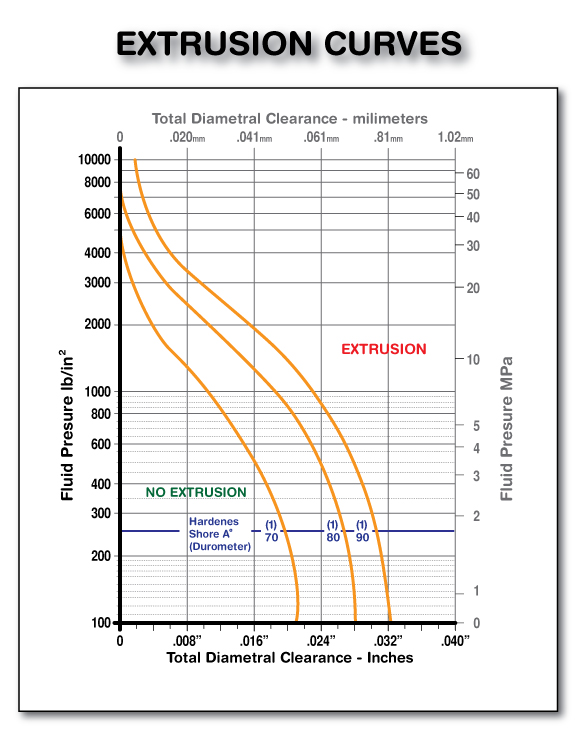

High pressure differentials across seal glands in your equipment can

cause low modulus rubber seals to extrude into the clearance between

mating surfaces.

Extrusion resistant rubber is essential for

trouble-free sealing when your equipment operates with high pressure

differentials and clearance gaps exceeding press-fit dimensions. Seals

Eastern's RGD resistant materials are highly extrusion resistant

within their respective polymer types.

High pressure differentials across seal glands in your equipment can

cause low modulus rubber seals to extrude into the clearance between

mating surfaces.

Extrusion resistant rubber is essential for

trouble-free sealing when your equipment operates with high pressure

differentials and clearance gaps exceeding press-fit dimensions. Seals

Eastern's RGD resistant materials are highly extrusion resistant

within their respective polymer types.

|

ASTM D1418 |

Compound No. |

Shore-A Hardness |

Description |

|---|---|---|---|

| EPDM | 7204 | 90 | Y267-Type EPDM for geothermal steam service; Ultra-Low compression set |

| FKM | 7248 | 95 | RGD / ED resistant FKM rubber: ISO-23936-2 certified; Extrusion resistant |

| FEPM | 7182D | 80 | Formulated AFLAS® high-temperature "sour" oil & gas service. RGD / ED resistant. Excellent acid and base resistance |

| FEPM | 7182B | 90 | Formulated AFLAS® high-temperature, high-pressure carbon dioxide and "sour" oil & gas service; RGD / ED resistant: NORSOK M-710 certified; Excellent acid and base resistance |

| FEPM | 7182A | 95 | Formulated AFLAS® high-temperature, high-pressure carbon dioxide and "sour" oil & gas service; ED / RGD resistant; Excellent acid and base resistance |

| D1418 | Compound | Thickness | 5000 PSI @ 120°C | 11,700 PSI @ 60°C | 11,700 PSI @ 120°C |

|---|---|---|---|---|---|

| FEPM | 7182D | .210 | 0000, 0000 | 0000, 0000 | 0000, 0000 |

| FEPM | 7182B | .210 | 0000, 0000 | 0000, 0000 | |

| FEPM | 7182B | .139 | 0000, 0000 | 0000, 0000 |

Premium Quality Seals...

For a Cleaner, Safer, More Reliable World.TM