Seals Eastern, Inc.

Machine Shop & Manufacturer

Highly Engineered Metal Components, MoldMaking, Tool & Die

Tel: 732-747-9200

Tel: 732-747-9200

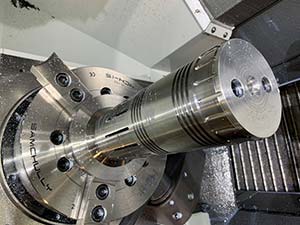

When you require precision cut metal components, Seals Eastern has a

captive machine shop facility equipped with

state-of-the-art CNC mill, lathe, and drilling operations to

consistently meet your specifications. SolidWorks and Surfcam are the

platform for our design work and allow us to generate programmed

tool-paths which are downloaded to our numerically controlled

equipment. We utilize

Live Tooling

by HAAS on our ST-40 lathes to expedite the manufacture of components

that require both lathe and mill work. Our facility produces tight

tolerance engineered metal components and tooling that gives Seals

Eastern the ability to manufacture the highest quality precision

molded rubber products.

When you require precision cut metal components, Seals Eastern has a

captive machine shop facility equipped with

state-of-the-art CNC mill, lathe, and drilling operations to

consistently meet your specifications. SolidWorks and Surfcam are the

platform for our design work and allow us to generate programmed

tool-paths which are downloaded to our numerically controlled

equipment. We utilize

Live Tooling

by HAAS on our ST-40 lathes to expedite the manufacture of components

that require both lathe and mill work. Our facility produces tight

tolerance engineered metal components and tooling that gives Seals

Eastern the ability to manufacture the highest quality precision

molded rubber products.

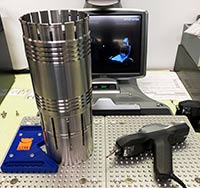

Seals Eastern's machine shop is equipped with modern HAAS lathes,

mills, and supporting equipment to handle your needs for tight

tolerance, highly engineered metal components with or without

engraving. We operate as both a job shop and continuous process

manufacturer with the ability to manufacture intricate metal

components numbering from a few units to hundreds of units per month.

Modern Keyence digital measuring equipment helps verify the high

quality that Seals Eastern is renowned for and provides highly

accurate first article measurements and reports available for your

quality assurance records. To be sure that you receive the best

quality, we only invest in the finest equipment and have attracted a

team of highly skilled and dedicated craftsmen. Our quality control

systems are ISO certified and can readily support any special quality

requirements you might have.

Seals Eastern's machine shop is equipped with modern HAAS lathes,

mills, and supporting equipment to handle your needs for tight

tolerance, highly engineered metal components with or without

engraving. We operate as both a job shop and continuous process

manufacturer with the ability to manufacture intricate metal

components numbering from a few units to hundreds of units per month.

Modern Keyence digital measuring equipment helps verify the high

quality that Seals Eastern is renowned for and provides highly

accurate first article measurements and reports available for your

quality assurance records. To be sure that you receive the best

quality, we only invest in the finest equipment and have attracted a

team of highly skilled and dedicated craftsmen. Our quality control

systems are ISO certified and can readily support any special quality

requirements you might have.

We can help you with multiple material requirements: We are able to work with carbon steels, stainless steels, aluminum, and various alloys. Non-metallic cutting is also available whether you require rings made from PEEK, PTFE, UHMWPE, or rubber.

Premium Quality Seals...

For a Cleaner, Safer, More Reliable World.TM