Seals Eastern has always approached both rubber formulation and the application of rubber in systems by using scientific disciplines. Our motto is simple, "Rubber is an Engineering Material". It is upon this most basic premise that Seals Eastern has been so successful in solving customer's sealing problems for nearly sixty years. We have invested a million dollars in analytical instruments, testing instruments, measuring devices, and a comprehensive technical library. Our technical papers online represents only a small number of the numerous papers and chapters published by Seals Eastern.

Seals Eastern's Material Development Center includes state-of-the-art instruments for the analysis of cured rubber, uncured rubber, and rubber compounding ingredients. The laboratory is equipped with instruments for Research and Development as well as Quality Assurance. This facility is charged with the following objectives:

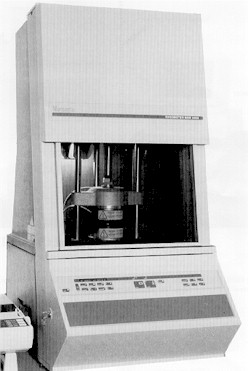

Used to characterize the cure profile for all Seals Eastern compounds.

A sample of uncured rubber is placed between the rheometer plates; the

plates are then closed, forming a sealed cavity. The plates are

maintained at 330° F while one plate oscillates. The stationary plate

is equipped with a torque transducer, which records the induced torque

as time and curing progress. When proper manufacturing controls are in

place, the resulting data creates a rheological "fingerprint" to

ensure our mixing process is under statistically proven control. The

result is consistently high quality rubber for you.

Used to characterize the cure profile for all Seals Eastern compounds.

A sample of uncured rubber is placed between the rheometer plates; the

plates are then closed, forming a sealed cavity. The plates are

maintained at 330° F while one plate oscillates. The stationary plate

is equipped with a torque transducer, which records the induced torque

as time and curing progress. When proper manufacturing controls are in

place, the resulting data creates a rheological "fingerprint" to

ensure our mixing process is under statistically proven control. The

result is consistently high quality rubber for you.

Seals Eastern utilizes Fourier transformed infrared spectral data for

Quality Control and chemical analysis of

rubber compounds and ingredients. Seals Eastern employs a computer

integrated FTIR instrument to perform such analysis. We use the

Nicolet® Model 460 bench combined with a Spectra-Tech Thunderdome ATR

(Attenuated Total Reflectance) accessory as an extremely powerful tool

for analysis of elastomer composition and chemical degradation. FTIR

enables us to examine the presence or changes of functional organic

groups present within the rubber composition. Using this technology,

we can help you determine if you have the correct material in your

seals and furthermore help you analyze any field problems you might be

having with your seals.

rubber compounds and ingredients. Seals Eastern employs a computer

integrated FTIR instrument to perform such analysis. We use the

Nicolet® Model 460 bench combined with a Spectra-Tech Thunderdome ATR

(Attenuated Total Reflectance) accessory as an extremely powerful tool

for analysis of elastomer composition and chemical degradation. FTIR

enables us to examine the presence or changes of functional organic

groups present within the rubber composition. Using this technology,

we can help you determine if you have the correct material in your

seals and furthermore help you analyze any field problems you might be

having with your seals.

Seals Eastern utilizes an ARES to characterize and analyze the

viscoelastic properties of its materials. The ARES Strain-Controlled

Rheometer, by Rheometric Scientific, is an advanced instrument capable

of mechanical polymer characterization.

The instrument is capable of a wide range of testing from steady shear

to multi-wave temperature sweeps. The instrument is capable of testing

in the temperature range of -150° C to 600° C. Dynamic tests can be

performed at frequencies between 10-5 rad/s and 500 rad/s. Flow and

stress relaxation phenomena are easily observed using the ARES

instrument. To learn more about Dynamic Mechanical Thermal

Analysis read

Luckenbachs paper (note:

you will need Acrobat Reader to down load this paper).

The instrument is capable of a wide range of testing from steady shear

to multi-wave temperature sweeps. The instrument is capable of testing

in the temperature range of -150° C to 600° C. Dynamic tests can be

performed at frequencies between 10-5 rad/s and 500 rad/s. Flow and

stress relaxation phenomena are easily observed using the ARES

instrument. To learn more about Dynamic Mechanical Thermal

Analysis read

Luckenbachs paper (note:

you will need Acrobat Reader to down load this paper).

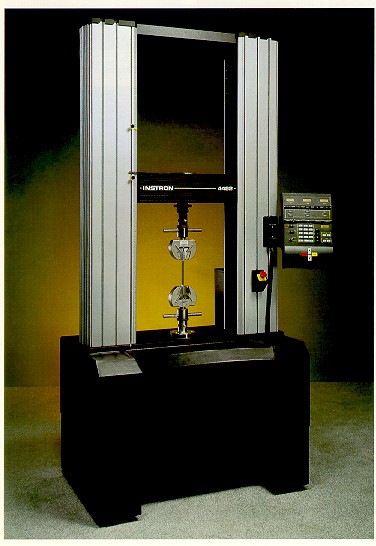

For standard (and some non-standard) measurements of rubber

properties, Seals Eastern, Inc. has two Instron tensile testing

machines. The Model 4400R and Model 1122 are equipped to perform

tensile and peel tests of virtually any rubber compound. Both machines

are computer integrated for precise data collection and generation of

stress - strain curves as well as integration of the area under the

stress- strain curves. Standard tests include: ASTM D429 Method B Peel

Test, ASTM D1414 O-Ring Tests, ASTM D412 Tensile Tests.

For standard (and some non-standard) measurements of rubber

properties, Seals Eastern, Inc. has two Instron tensile testing

machines. The Model 4400R and Model 1122 are equipped to perform

tensile and peel tests of virtually any rubber compound. Both machines

are computer integrated for precise data collection and generation of

stress - strain curves as well as integration of the area under the

stress- strain curves. Standard tests include: ASTM D429 Method B Peel

Test, ASTM D1414 O-Ring Tests, ASTM D412 Tensile Tests.

We possess a Differential Scanning Calorimeter (DSC) to measure the

heat flow produced in a rubber sample when it is heated, cooled, or

held isothermally at constant temperature. This technique enables us

to investigate exothermal events caused by crystallization or

endothermal melting processes. The resulting information offers clues

regarding thermal stability of a material. When used in seal failure

forensic work, the information offers insight regarding thermal

experience of the seal and/or characteristic of an absorbed transient

material.

We possess a Differential Scanning Calorimeter (DSC) to measure the

heat flow produced in a rubber sample when it is heated, cooled, or

held isothermally at constant temperature. This technique enables us

to investigate exothermal events caused by crystallization or

endothermal melting processes. The resulting information offers clues

regarding thermal stability of a material. When used in seal failure

forensic work, the information offers insight regarding thermal

experience of the seal and/or characteristic of an absorbed transient

material.

Thermogravimetric Analysis allows us to monitor the mass of a rubber

sample as a function of temperature or time as the sample specimen is

subjected to a controlled temperature program in a controlled

atmosphere. Upon heating a rubber compound, its weight increases or

decreases depending upon various molecular constituents in the

compound. The data produced by this instument provides additional

information regarding thermal experience of the seal and/or

characteristic of an absorbed transient material.

Thermogravimetric Analysis allows us to monitor the mass of a rubber

sample as a function of temperature or time as the sample specimen is

subjected to a controlled temperature program in a controlled

atmosphere. Upon heating a rubber compound, its weight increases or

decreases depending upon various molecular constituents in the

compound. The data produced by this instument provides additional

information regarding thermal experience of the seal and/or

characteristic of an absorbed transient material.

Premium Quality Seals...

For a Cleaner, Safer, More Reliable World.TM